rockwell hardness test load range|rockwell c hardness scale examples : Brand Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell . WEBCruz Azul won 25 direct matches. Pachuca won 20 matches. 11 matches ended in a draw . On average in direct matches both teams scored a 2.75 goals per Match. Cruz Azul in .

{plog:ftitle_list}

web你想要免费游玩各种精彩的 PC 游戏吗?那就赶快来Epic游戏商城吧!每周都有不同的游戏免费领取,无需花费一分钱,只需下载Epic Games 启动器,就可以畅玩无数的平台游戏、模组、DLC 等。不要错过这个难得的机会,立即加入免费游戏社区,享受Epic游戏商城带给你的无 .

The major load may be any of the following loads: 15kgf, 30 kgf, or 45 kgf. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Find it here.Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell . The Rockwell scale is a hardness scale based on indentation .

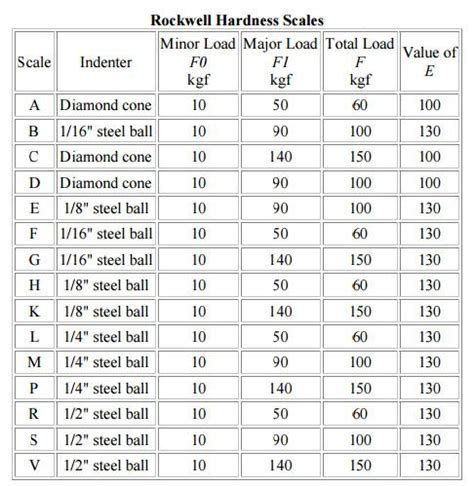

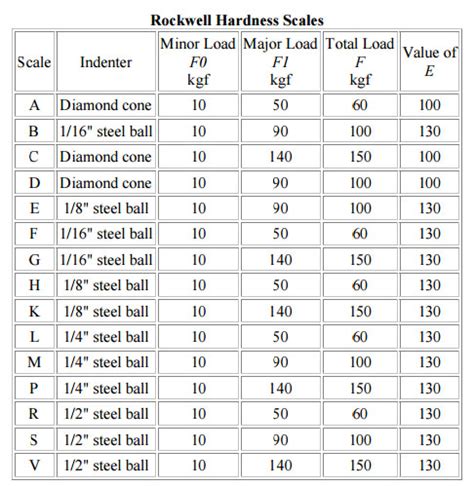

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .

Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in the “Regular” Rockwell scale). Total test forces range from 15kgf to 150 kgf (superficial and regular) to 500 to 3000 kgf . The various indenter varieties and range of test loads form a matrix of Rockwell hardness scales, which can be applied to a wide range of materials. Every Rockwell hardness scale is identified by a letter signifying the indenter .The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 and 150 kg. Creep and elastic recovery factors are involved in determining the Rockwell hardness.

In regular Rockwell testing the minor load is always 10 kgf (kilograms of force). The major load can be any of the following loads: 60 kgf, 100 kgf or 150 kgf. No Rockwell hardness value is specified by a number alone.The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. 2 Brinell Hardness. The Brinell hardness test involves indenting a material with a .There are two general classes of Rockwell test: Rockwell and superficial Rockwell. In Rockwell testing, the minor load is 10 kgf and the major load is 60, 100 or 150 kgf.Most alloys in knife blades range from soft steels in the RC45 range to hard metals rated in the RC60 category. It’s a misconception to think high RC ratings mean better-quality knives. It depends entirely on a blade’s intended use as to .

Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, .

rockwell r scale conversion chart

In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. . HR is the abbreviation for Rockwell hardness. C represents a load .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method.

torsion test lab report utem

What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the . In the Rockwell hardness test, an indenter is pressed into the material. . Figure: Rockwell hardness test procedure. The actual test load F 1 is applied in addition to the preload and the indetor penetrates the material with the total force F=F 0 +F1. The test load to be set is taken from table books depending on the indenter and the material .These indenters are unique to the Rockwell hardness test alone. Test Load – The range of loads and the combination of initial minor loads and final major loads also distinguishes the Rockwell method from other test methods. The applied load ranges from 15kgf to 150kgf, where a 3kgf is usually the minor load before applying the major loads .

Applied range: HRA: Diamond cone: 588.4: 20-88: . The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values obtained from different scales are not comparable. . Vickers hardness test: Low load Vickers test: Micro Vickers hardness test . The various indenter varieties and range of test loads form a matrix of Rockwell hardness scales, which can be applied to a wide range of materials. Every Rockwell hardness scale is identified by a letter signifying the indenter type and the two loads used for the test.Methods: Vickers, Knoop and Brinell hardness testing; Load range: selectable ranges between 0,1gf and 62,5kgf; Semi-automatic and fully automatic micro/macro tester . Vickers, Knoop, Brinell and Rockwell hardness testing; Load ranges: 200 gf - 250kgf, 200 gf - 750 kgf, 200 gf - 3000 kgf; Automatic eight-position turret + combined touch probe .

rockwell hardness tester scale

automatic load sequence, with only simple handling test possibility. The digital type (HR-320MS, HR-430MR and HR-430MS) has a digimatic . Total test force Hardness range applicable Rockwell Superficial hardness 15N HR15N Conical diamond 29.42N (3kgf) Coverage 147.1N (15kgf) 70-94HR15N Load Range (kgf*) Indentation Type: Standards: Rockwell C (HRC) Metals, Alloys: Quick, easy to use, widely recognized: . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. Here’s a step-by-step of the process:

In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to overcome the problem of cracking in brittle materials. . Find out more about the Rockwell hardness test. Jominy .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. . The various indenter types combined with a range of test loads form a matrix of Rockwell hardness scales that are applicable to a wide variety of materials. . diameter tungsten-carbide ball and the major load is 100kg .

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads .

Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C . Rockwell Hardness Testing Theory. Rockwell hardness testing has several indenter types which in turn require separate major loads (kg). Figure 1 reflects common Rockwell scales used and their corresponding major .

The Rockwell hardness test is based on the difference of indenter depth from two load . In Rockwell testing, the minor load is 10 kgf and the major load is 60, 100 or 150 kgf. In superficial Rockwell testing, the minor load is 3 kgf and major load is 15, 30 or 45 kgf. . 8.3.2 Verify Range of Testing A. Select an appropriate combination of . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. search. Search search close search cart. facebook twitter linkedin youtube . • Superficial Rockwell: the minor load is 3 kgf and major load is 15, 30 or 45 kgf. In both tests, the indenter may be either a diamond cone or steel ball, depending on the .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

rockwell hardness tester diagram

The Rockwell hardness test has a variety of applications. It is not only used to determine material properties according to hardness and forming processes, but also for quick and effective testing in production and incoming goods departments. . Our portable Rockwell hardness testers in a load range of 15 to 187.5 kg are the product of over 65 .Test Load range 1-187.5 kgf (9,81 - 1838,7 N) Test load type Closed loop Indenter holder Snap grip Available indenters Rockwell: Rockwell diamond cone 120°, 1/16”, 1/8”, ¼”, ½” carbide ball indenters Brinell: 1mm, 2.5mm, 5mm and 10mm ball indenters Rockwell test procedures ISO 6508-1, ASTM E18

Rockwell hardness tester for load range of 10 to 150 kg & 3 to 45 kg with touch screen. Jump to the content of the page. English. . ZHR8150 Rockwell and Superficial Rockwell hardness testing instrument; Building on the long-lasting quality and success of the previous ZHR series, with a brand new touch screen display to make Rockwell hardness .3.1. Rockwell Hardness Test. . , 1,500, or 500 kgf, so that the diameter of the indentation is in the range 2.5 to 6.0 mm. The load is applied steadily without a jerk. The full test load is applied for 10 to 15 seconds. Two diameters of impression at right angles are measured, .

Macro hardness testing for your production or laboratory processes according to Vickers, Knoop, Brinell, Rockwell, carbon testing & plastics testing Load range from 0.3 to 3,000 kg More information and request for quotation

Rockwell Hardness Scale. The Rockwell Hardness Scales comprise various types, depending on the material to be tested. Each scale utilizes different loads or indenters, and permits the testing of materials with different hardness. For instance, the HRB scale is employed for testing soft steels, aluminium, and brass, and involves applying minor .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . returning the force to the preliminary load. After holding the preliminary test force for a specified time, the final indentation is measured. . test loads (preloads) range from 3 kgf (used in the "Superficial" Rockwell scale) to 10 .

torsion test lab report uthm

torsion test labeled graph

web9 de dez. de 2016 · Check-Raise: 先check不下注,目的是之后可以加注对手们的下注.当你觉得你有一副好牌的时候,这种技巧可用来吸引更多筹码到台面上 Cold call: 冷跟,在很靠前位置的玩家raise示强时候,紧接着的玩家call,用来表示call的玩家也有很强的牌。

rockwell hardness test load range|rockwell c hardness scale examples